Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:www.dllongyao.com

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:www.dllongyao.com

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

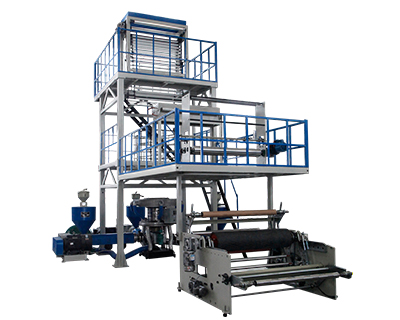

The three-layer co extrusion blown film machine, as a key equipment for efficient production of composite plastic films, is widely used in fields such as food packaging, pharmaceutical packaging, and agricultural film. Its operation involves multi system collaboration (heating, extrusion, cooling, traction, winding). Improper operation not only affects the quality of the film, but may also cause safety accidents.

1、 Preparation before startup: Details determine safety and quality

Equipment inspection

Confirm that all systems (heating, cooling, traction, winding) are connected properly and without looseness or damage; The emergency stop button, protective cover and other safety devices are complete and effective.

Check the cleanliness of the mold: The feed inlet and flow channel of the three-layer mold head should be free of residual material blocks or impurities to avoid black spots and crystal dots on the film layer; Adjust the die gap to meet the process requirements (usually set according to the film thickness).

Lubrication system: Check the lubricating oil level of moving parts such as gearboxes and bearings, and replenish it in a timely manner if it is insufficient; Confirm that the traction roller and guide roller are not stuck.

Preparation of raw materials

The three-layer raw materials need to correspond to the process requirements (such as inner PE, middle EVOH barrier layer, outer PE), and the dryness of the raw materials should be checked (moisture content ≤ 0.1%). Wet raw materials need to be dried in advance (such as PE drying temperature of 60-80 ℃, EVOH drying temperature of 100-120 ℃).

Before adding raw materials to the hopper, they need to be sieved to remove impurities; Ensure that there is no mixing in the hopper (different grades of raw materials are stored separately).

Parameter Settings

Set the temperature of each section according to the characteristics of the raw materials: the temperature of the barrel, screw, and mold head needs to be adjusted layer by layer (such as PE barrel temperature of 150-180 ℃, EVOH barrel temperature of 180-220 ℃), and preheat for 30-60 minutes until the temperature stabilizes (to avoid local overheating).

Set initial parameters such as air ring cooling temperature, traction speed, and winding tension (the initial value of traction speed is less than 50% of the normal operating speed).

2、 Startup operation: gradual and coordinated

Start sequence

First, turn on the cooling water (mold, barrel cooling circuit) → start the heating system (confirm that the temperature reaches the set value) → start the extruder (low-speed operation, speed 5-10rpm) → wait for the uniform discharge from the mold mouth, start the air ring → start the traction machine (low-speed traction, synchronously adjust the position of the film bubble) → start the coiler.

Membrane bubble adjustment

When bubbles appear, gently hold the bubbles with your hands (wear heat-resistant gloves) to avoid displacement; Adjust the air volume of the air ring (the inner air ring controls the stability of the film bubble, and the outer air ring controls the cooling speed) to ensure that the film bubble is vertical without shaking.

Gradually increase the extruder speed and traction speed, synchronously adjust the proportion of the three-layer extrusion volume (by controlling the motor current of each layer through a frequency converter), and ensure uniform thickness of the three layers (such as 30% for the inner layer, 20% for the middle layer, and 50% for the outer layer).

Thickness calibration

Use a thickness gauge to measure the thickness of each point on the film, adjust the die gap or extrusion speed of each layer to ensure a thickness deviation of ≤± 5%; Confirm that the width and transparency of the film meet the requirements (without wrinkles or bubbles).

3、 Operation monitoring: real-time warning, timely adjustment

Key indicator monitoring

Bubble state: Observe whether the bubble is stable (without offset or rupture), and whether the surface is smooth (without scratches or crystal dots); If bubbles appear, it is necessary to check the dryness of the raw materials or whether there are impurities in the mold mouth.

Equipment parameters: Real time recording of temperature, motor current, and traction speed in each section; When the temperature fluctuation exceeds ± 5 ℃, adjust the heating power in a timely manner; Abnormal increase in current (exceeding 10% of rated value) requires shutdown inspection (such as screw jamming).

Raw material supply: Ensure that the material level in the hopper is ≥ 1/3 to avoid material breakage (which can cause sudden changes in film thickness and even damage to the screw).

exception handling

Membrane bubble deviation: adjust the distribution of air flow in the air ring or the angle of the traction roller;

Uneven thickness: adjust the extrusion speed or die gap of the corresponding layer;

Motor abnormal noise: Stop immediately and check the lubrication condition of the bearings or gearbox;

Fire hazard: If the raw materials melt excessively and smoke, immediately cut off the power and use a dry powder fire extinguisher to extinguish the fire (water is prohibited).

4、 Shutdown process: standardize operation, protect equipment

Gradually shut down

Reduce the extruder speed to 5rpm → Stop extrusion → Turn off the heating system → Wait until the temperature drops below 100 ℃, stop pulling and coiling → Close the air ring → Cut off the cooling water.

Equipment cleaning

Clean the mold head while it is hot: use a copper brush (to avoid scratching the mold mouth) to remove residual material, and then use a cotton cloth dipped in a special cleaning agent to wipe it;

Cleaning hopper: The remaining raw materials are sealed and stored, and there is no residue in the hopper;

Clean the traction roller and guide roller: remove film residue and avoid adhesion.

Record and organize

Fill in production records (film specifications, output, equipment parameters, abnormal situations); Organize on-site tools and keep the area around the equipment clean.

5、 Daily maintenance: Extend equipment lifespan

regular inspection

Weekly inspection of screw and barrel wear (such as PE screw wear ≤ 0.1mm/1000 hours); Check the rubber layer of the traction roller monthly for aging (replace it promptly if cracks appear);

Replace gearbox lubricating oil every quarter (model according to equipment manual); Perform insulation testing on the electrical system annually to avoid electrical leakage.

Replacement of vulnerable parts

Filter screen (replaced every 8-12 hours of production): prevents impurities from entering the mold head;

Seals (such as cylinder flange gaskets): to prevent material leakage;

Heating coil (replace it promptly if it does not heat up).

6、 Safety regulations: The red line cannot be crossed

personnel protection

Operators must hold a certificate to work (trained and qualified by the equipment manufacturer); Wear work clothes, safety helmets, heat-resistant gloves, and protective goggles (slippers and shorts are prohibited).

Prohibited acts

During equipment operation, it is prohibited to touch high-temperature components such as mold heads and screws with hands (temperatures can reach over 200 ℃, which may cause burns);

It is prohibited to cross safety barriers or place tools at the operating parts of equipment;

During maintenance, the power must be cut off and a "Do not close" warning sign must be hung to avoid accidental operation;

It is prohibited to stack flammable materials (such as raw material bags) around the equipment, and fire extinguishing equipment (dry powder, CO ₂) should be equipped.

Emergency handling

In case of material jamming, abnormal noise or fire, immediately press the emergency stop button;

When personnel are burned, rinse them with cold water and send them to the hospital; When electrocuted, cut off the power first and then rescue.

The operation of the three-layer co extrusion blown film machine needs to balance "quality" and "safety", from detailed preparation before startup to real-time monitoring during operation, and then to standardized maintenance after shutdown, every step must strictly follow the process requirements. Safety regulations are the bottom line of production. Only by keeping in mind the operating points and respecting equipment risks can efficient and stable production be achieved, ensuring the safety of personnel and equipment.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088/0411-86268988

BM:0411-86265066

Web:www.dllongyao.com

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Mobile station

Copyright ©Http://Www.Dllongyao.Com/En/ Dalian Longyao Plastic Machinery Co., Ltd Specializing inPE Film Blowing Machine,Three Layer Coextrusion Film Blowing Machine,ABA Film Blowing Machine, Welcome to inquire!

辽ICP备14017684号 Powered By Xiangyun platform Technical support: joint enterprise Era