Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:www.dllongyao.com

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:www.dllongyao.com

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

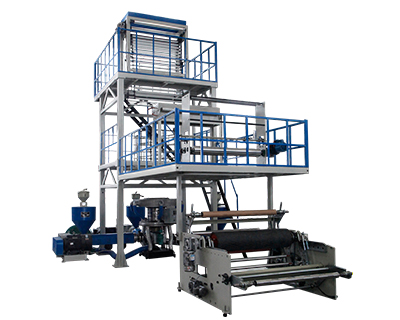

The three-layer co extrusion blown film machine has broad application prospects in the market due to its multifunctionality, high efficiency, and environmental friendliness. Especially in the fields of food packaging, pharmaceutical packaging, and environmentally friendly materials, the demand for three-layer co extruded films will continue to grow. In addition, with the continuous advancement of technology, the production efficiency and product quality of equipment will be further improved, further promoting the development of the market.

Through co extrusion technology, films with multi-layer structures can be produced, and different properties such as strength, transparency, and barrier properties can be selected for each layer according to the needs, thus meeting diverse application requirements. Multilayer films have excellent mechanical properties, barrier properties, heat resistance, etc., and are widely used in high demand packaging fields. By designing the thickness and properties of each layer of material reasonably, material costs can be reduced while ensuring the performance of the film.

How to choose a high-quality three-layer co extrusion blown film machine?

Screw and barrel

Plasticization ability: The screw should have high plasticization ability, which can achieve high output while ensuring plasticization quality. It can be judged by understanding the design structure, aspect ratio, and other parameters of the screw. Generally speaking, screws with a larger aspect ratio have better plasticizing effects.

Material and Quality: The screw and barrel should be made of high-quality wear-resistant and corrosion-resistant materials, such as bimetallic alloys, to extend their service life. Check whether the surface of the screw is smooth, and whether there are defects such as wear, scratches, or cracks.

Adaptability: A good screw should be able to adapt to the processing of various plastic materials and have strong flexibility for different production needs.

Die head

Uniformity of discharge: The structural design of the mold head should be reasonable to ensure that the three-layer plastic melt can be evenly extruded, resulting in good thickness uniformity of the film. Observe whether the flow channel design of the mold head is smooth, and whether there are any dead corners or blockages. High quality molds should be able to ensure that the thickness tolerance of the film is controlled within a small range during discharge.

Material and processing accuracy: The mold head is usually made of corrosion-resistant and wear-resistant steel, and undergoes high-precision processing and surface treatment, such as hard chrome plating, to improve its wear resistance and corrosion resistance, while ensuring the surface quality of the film.

control system

Automation level: Advanced control systems can achieve precise control of process parameters such as temperature, speed, and pressure, improving production stability and product quality consistency. For example, a control system with automatic adjustment of screw speed, traction speed, inflation ratio, and other functions can reduce manual intervention, lower operational difficulty, and labor intensity.

Operation interface: The operation interface should be simple and intuitive, easy to operate and understand, and convenient for operators to set parameters, monitor equipment operation status, and diagnose faults. At the same time, the control system should have good human-computer interaction functions, which can timely display the operation information and alarm prompts of the equipment.

Cooling system

Cooling effect: The cooling system is crucial for the formation of thin films and should have a good cooling effect to quickly cool and shape the extruded film, thereby improving production efficiency and film quality. It can be examined whether the design of the cooling air ring is reasonable, whether the air outlet is uniform, and whether the air volume and speed of the cooling fan can be adjusted.

Stability: The operation of the cooling system should be stable and reliable, with good temperature control capabilities, able to maintain consistency in cooling temperature, and avoid affecting the performance and quality of the film due to temperature fluctuations.

Traction and winding device

Traction accuracy: The traction device should be able to accurately control the traction speed of the film, ensure stable tension of the film during production, and avoid problems such as uneven stretching or wrinkling of the film. High precision traction devices can also improve the dimensional accuracy and stability of thin films.

Winding quality: The winding device should be able to neatly roll the film into a roll, avoiding phenomena such as curling edges, loose rolls, or staggered layers. At the same time, it should have automatic roll changing function to improve production efficiency.

By combining different materials, films with multiple functions can be produced, such as high barrier properties, anti-static properties, weather resistance, etc. The three-layer co extrusion technology can combine high-performance materials with low-cost materials, reducing production costs while ensuring performance. The impact on the environment can be reduced by using biodegradable or recycled materials. High degree of automation, high production efficiency, suitable for large-scale production.

Used for food packaging, pharmaceutical packaging, cosmetics packaging, etc., providing excellent barrier performance, mechanical strength, and aesthetics. Used for producing agricultural film, such as plastic film, greenhouse film, etc., it has good weather resistance, UV resistance, and insulation performance. Used for producing thin films for construction, such as waterproof films, soundproof films, etc., providing excellent waterproof, soundproof, and thermal insulation performance. Used for producing industrial packaging films, such as wrapping films, shrink films, etc., providing high strength and good tensile properties.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088/0411-86268988

BM:0411-86265066

Web:www.dllongyao.com

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Mobile station

Copyright ©Http://Www.Dllongyao.Com/En/ Dalian Longyao Plastic Machinery Co., Ltd Specializing inPE Film Blowing Machine,Three Layer Coextrusion Film Blowing Machine,ABA Film Blowing Machine, Welcome to inquire!

辽ICP备14017684号 Powered By Xiangyun platform Technical support: joint enterprise Era