Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:www.dllongyao.com

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:www.dllongyao.com

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

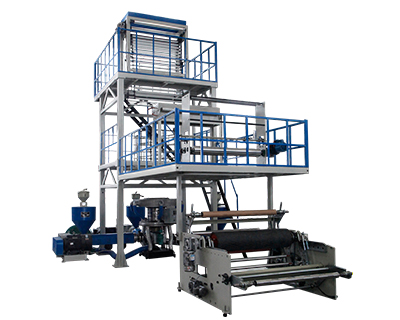

The three-layer co extrusion blown film machine, as an advanced packaging equipment, plays an important role in the packaging industry and promotes the rapid development of the packaging industry. In the future, with the continuous innovation of technology and the constant changes in market demand, the three-layer co extrusion blown film machine will continue to play an important role and continuously optimize and improve to adapt to future development trends.

The three-layer co extrusion blown film machine is suitable for producing food packaging film, pharmaceutical packaging film, liquid packaging film, agricultural film covering and other fields. It can not only produce three-layer composite films with excellent physical properties, but also has advantages such as high production efficiency, stable quality, and simple operation. At the same time, the device can also be customized and designed according to customer needs, providing personalized solutions.

What are the considerations for model selection and parameter configuration of a three-layer co extrusion blown film machine?

What needs to be considered are production specifications and requirements. Select the appropriate model and configuration parameters based on the required film width, thickness, material, and other requirements for production. Different specifications and requirements can affect the production capacity and effectiveness of equipment, so it is necessary to make a reasonable selection based on the actual situation.

Secondly, the performance and quality of the equipment need to be considered. When choosing a three-layer co extrusion blown film machine, attention should be paid to the performance and quality of the equipment in terms of extrusion capacity, tensile performance, control system, and other aspects. High performance and high-quality equipment can improve production efficiency and product quality, reduce production costs, and have a longer service life.

Again, it is necessary to consider the applicability and flexibility of production. When choosing a three-layer co extrusion blown film machine, it is necessary to consider the applicability of the equipment and the flexibility of production. Some devices can be adjusted and set according to different production requirements, with better applicability and flexibility, and can produce a wider range of products.

In addition, it is necessary to consider the maintenance and upkeep of the equipment. When choosing a three-layer co extrusion blown film machine, it is necessary to consider the maintenance and upkeep of the equipment. Some devices are equipped with automated maintenance systems, which can improve the stability and reliability of the equipment and reduce the number of failures and repairs during the production process.

The working principle of the three-layer co extrusion blown film machine is to heat and melt plastic particles, extrude them into shape through screws, cool them through air rings, and then proceed with subsequent processing through other auxiliary equipment such as coilers and presses. The entire production process requires strict control of parameters such as temperature, extrusion speed, and air pressure to ensure that the three-layer film has uniform thickness and good physical properties.

The working principle of the three-layer co extrusion blown film machine is to first add three different colors or materials of plastic particles into three extrusion mechanisms, and after heating, melting, and extrusion, the three molten plastics are simultaneously extruded through the extrusion port, and form a three-layer film structure through the gear pump and extrusion mechanism. Then, the molten film is rapidly cooled and solidified by a cooling roller, and the film is stretched to the desired width and thickness by a traction roller. Finally, the finished film is collected by a coiling roller.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088/0411-86268988

BM:0411-86265066

Web:www.dllongyao.com

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Mobile station

Copyright ©Http://Www.Dllongyao.Com/En/ Dalian Longyao Plastic Machinery Co., Ltd Specializing inPE Film Blowing Machine,Three Layer Coextrusion Film Blowing Machine,ABA Film Blowing Machine, Welcome to inquire!

辽ICP备14017684号 Powered By Xiangyun platform Technical support: joint enterprise Era