Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:www.dllongyao.com

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:www.dllongyao.com

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

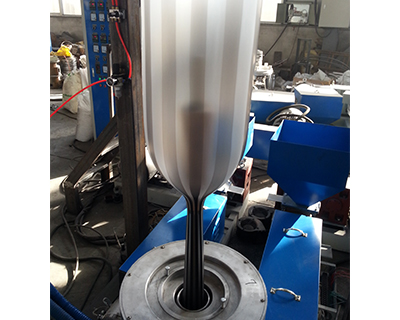

In the process of film production, three-layer co-extrusion blower, due to the presence of a large number of rollers, rubber rollers and metal rollers, causes a large amount of friction on the insulated film material, which can produce high static electricity up to 100,000 volts, which seriously affects the product quality, production efficiency and production safety. Therefore, in high-speed applications such as slicing, striping, coating and rewinding, the static electricity must be effectively eliminated.

The operator must not stand in front of the machine to avoid accidental injury to the operator. When feeding, it is strictly prevented that hard objects with metal impurities and operating gadgets that damage the machine fall into the barrel. Do not wear gloves when operating the rotating machine to prevent involvement. Check and improve the lubrication in the reducer and air compressor, and check the lubrication of each mechanical drive unit.

Avoid damaging the machine and making noise during dry operation. During power-on operation, it is necessary to check each power connection for disconnection or leakage. Check whether the instrument is damaged or not. Make sure all parts are safe and normal before starting up, so as not to affect production and cause accidents. Increase the forming temperature, the cooling air temperature and the blowing ratio within the film forming conditions. Then the film turbidity increases and the gloss decreases. Conversely, increase.

When the die outlet is uniform and uniform, gloves can be worn to slowly lift the tube blank, while the end of the tube blank is closed, the air inlet control valve is slightly opened so that a small amount of compressed air is put into the center hole of the mandrel, and then carefully guided through the bubble holder, the herringbone, and put into the traction roll, guide roll until roll up (for example, the embossing roll) to blow out the tube blank with appropriate compressed air pressure. It can not make the billet crack, but also ensure the symmetry and stability of the membrane tube, which relatively guarantees the quality of production.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088/0411-86268988

BM:0411-86265066

Web:www.dllongyao.com

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Mobile station

Copyright ©Http://Www.Dllongyao.Com/En/ Dalian Longyao Plastic Machinery Co., Ltd Specializing inPE Film Blowing Machine,Three Layer Coextrusion Film Blowing Machine,ABA Film Blowing Machine, Welcome to inquire!

辽ICP备14017684号 Powered By Xiangyun platform Technical support: joint enterprise Era