Adhesion (commonly known as "sticking") on the surface of thin films in the production of PE blown film machines is a common problem, which may be caused by raw material formulation, process parameters, equipment performance, or environmental factors. The following are specific solutions and principle analysis:

1、 Adjustment of raw material formula

1. Add a lubricant or anti adhesive agent

Principle: Adding lubricants (such as oleic acid amide and erucic acid amide, with a dosage of 0.05% -0.3%) to the resin can reduce the surface friction coefficient of the film; Add anti adhesive agents (such as silica, calcium carbonate, particle size 2-5 μ m, dosage 0.5% -2%) to support the surface of the film through microscopic particles, forming an air layer to prevent adhesion.

matters needing attention:

Excessive amount of lubricant can cause precipitation (whitening) on the surface of the film, and the proportion should be adjusted according to the melt index of the raw material (low melt index raw materials can be added appropriately).

Anti adhesive agents need to be fully dispersed, otherwise it can easily cause mold blockage or increase in film crystal points.

2. Adjust the resin ratio

High and low density resin compounding:

Pure LDPE (low-density polyethylene) film has strong surface polarity and is prone to adhesion. It can be mixed with 10% -30% LLDPE (linear low-density polyethylene) or HDPE (high-density polyethylene) to reduce surface viscosity by utilizing differences in molecular chain structure.

For example, when blowing plastic wrap, a formula of 70% LDPE+30% LLDPE can be used to improve anti adhesion while maintaining flexibility.

Regenerated material ratio control: Residual additives or degradation products in the regenerated material may increase viscosity. It is recommended to use a regenerated material ratio of ≤ 50% and mix it with 1% -2% paraffin or stearic acid to improve fluidity.

2、 Optimization of process parameters

1. Reduce the melting temperature

Principle: Excessive temperature can lead to excessive plasticization of resin, increased molecular chain activity, and residual viscosity on the surface after cooling.

Operation method:

Gradually reduce the temperature of the barrel and die (5-10 ℃ each time), and observe the transparency and surface condition of the film.

Taking LDPE as an example, if the original temperature is 180 ℃, it can be attempted to lower it to 165-175 ℃, but it is necessary to ensure sufficient plasticization (no unmelted particles).

2. Adjust the inflation ratio and traction ratio

Inflation ratio:

Increasing the inflation ratio (such as from 2.0 to 2.5) can increase the lateral stretching of the film, making the molecular chain orientation more regular, the surface smoother and denser, and reducing the contact area.

However, a high inflation ratio can easily cause the film to become brittle, and it is necessary to increase the cooling air volume (see cooling system adjustment below).

Traction ratio:

Appropriately increase the traction ratio (such as from 15 to 20) to enhance the longitudinal tensile strength, while reducing the film thickness, lowering the weight per unit area, and reducing the contact pressure during stacking.

3. Strengthen the cooling effect

Wind ring adjustment:

Increase the air volume (turn on the outer fan of the dual outlet air ring), reduce the cooling temperature of the film, shorten the high-temperature residence time, and avoid surface melting and adhesion.

Adjust the height of the air ring (20-50cm from the mold head). If the air ring is too low, it can lead to uneven cooling, while if it is too high, it can affect the stability of inflation.

Water cooling assistance: If producing thick films (≥ 0.1mm) or high-speed working conditions, a water cooling roller (surface temperature controlled at 30-40 ℃) can be installed to forcibly reduce the surface temperature of the film.

3、 Equipment performance improvement

1. Maintenance of mold head and screw

Clean the mold head flow channel:

Regularly disassemble the mold head and use a copper brush or specialized cleaning agent to remove the accumulated material in the flow channel (especially in dead corners), to avoid the extrusion of degraded materials with the melt, which may cause the film surface to become sticky.

Check the gap between the mold heads (usually 0.8-1.5mm). Uneven gaps can cause inconsistent melt flow rates and local overheating and adhesion.

Screw wear repair:

After the wear of the screw thread, the decrease in plasticization efficiency may lead to the retention and degradation of the melt. It is necessary to restore the compression ratio by electroplating or replacing the screw with a new one (recommended compression ratio is 3-5).

2. Traction roller and winding adjustment

Surface treatment of traction roller:

Change the traction roller to a matte sandblasted surface or coated with a silicone layer (hardness 60-70 Shore A) to increase the roughness of the roller surface and reduce the adhesion force between the film and the roller surface.

Regularly clean the traction roller to remove any residual lubricant precipitates or oil stains on the surface.

Winding tension control:

Reduce the winding tension (such as from 8N to 5N) to avoid interlayer adhesion of the film due to excessive pressure during winding.

Adopting gap winding mode (i.e. retaining a small air layer between the winding roller and the film), or periodically pausing traction to reduce continuous compression.

4、 Environmental and post-processing interventions

1. Control the humidity of the production environment

High humidity environments can cause anti adhesive agents to lose moisture absorption. It is recommended to control the humidity in the workshop at 40% -60% RH. If the raw materials are prone to moisture absorption (such as those containing starch based additives), they need to be dried in advance (80 ℃, 2 hours).

2. Film post-treatment

Corona treatment: If adhesion is caused by low surface energy (such as pure LLDPE film), an additional corona treatment process (power 3-5 kW) can be added to increase surface tension to 38-42 mN/m, improving printability while reducing adhesion.

Physical isolation:

Insert thin paper or polypropylene barriers between the film rolls during winding to prevent long-term stacking and adhesion.

For finished films, "rolling and powder spraying at the same time" (talc powder or silica powder, dosage 5-10g/m ²) can be used, but attention should be paid to dust environmental protection issues.

5、 Suggestions for troubleshooting process

Step 1: Check if the raw materials have been misused (such as mixing high viscosity metallocene polyethylene), or if the additives are unevenly dispersed (which can be determined by comparing the retained samples).

Step 2: Test the process parameters, adjust the temperature and cooling first, and if it is ineffective, try changing the inflation ratio and traction ratio.

Step 3: Check the hardware of the equipment, such as mold head accumulation, screw wear, and the flatness of the traction roller. If necessary, stop the machine for maintenance.

Step 4: If all of the above are ineffective, it may be a design flaw in the formula (such as a lack of anti adhesion system), and the ratio of additives needs to be re optimized.

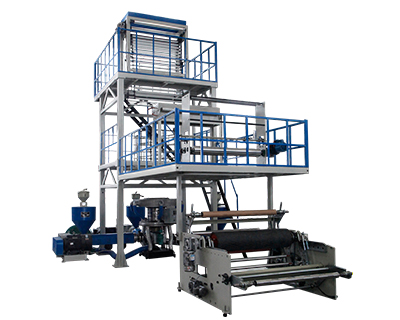

To solve the problem of film adhesion, it is necessary to start from multiple dimensions such as "formula process equipment environment". Priority should be given to quickly verifying additives and process parameters. If high demand films are produced for a long time (such as automatic packaging films), it is recommended to purchase models equipped with efficient cooling systems (such as dual air vents and water-cooled rollers), high-precision temperature control (± 1 ℃), and screw anti sticking coatings. A database of raw materials and processes should be established to record better production parameters for different formulas, in order to quickly respond to production fluctuations.