When the ABA film blower is thicker, loosen the screw. This is called the downward-adjusting head. If there is a large underneath opening, and you put in the upper mould, it is to loosen the thin side and tighten the thick side, which is called inversion. The head has four or six adjustment bolts, generally with an inner hexagon, at the top edge of the head.

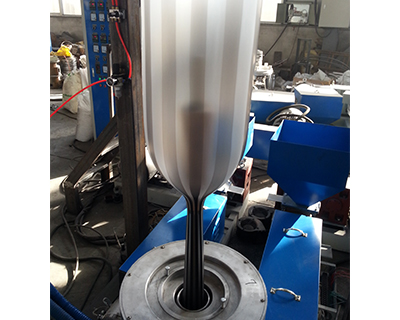

Adjust them, as to whether it is tight or loose, the moulds of different origins are different, you will know after you start. The main structure of the extruder is composed of extruder, head, die, cooling device, foam holder, herringbone, traction roll, coiling device, etc. 1: Extruder, extruder is mainly composed of screw, barrel hopper, deceleration and drive motor, drive motor is made of electromagnetic speed-regulating motor (also can be used with frequency conversion common motor).

Drive the decelerator by belt drive to rotate the screw in the barrel. The plastic melted in the hopper under external heating is extruded through three filters from the die to two-to-three-way through the die. The die consists of three parts: filter, filter plate and three-way pressure cover. The die 4: cooling device is composed of cooling air ring, air duct, blower, etc.

Traction, which is made up of traction rack, herringbone, traction roll, winding mechanism, traction motor and other major components, is suitable for all kinds of high-grade film packaging. Because of its good barrier, freshness-keeping, moisture-proof, frost-proof, oxygen-proof and oil-resistant, this kind of membrane can be widely used in light and heavy packaging. Such as a variety of fresh fruits, meat, pickles, fresh milk, liquid drinks, medical supplies and so on.